Tinnies

The mass production aluminum runabout, better known in Australia simply as the ‘tinnie’, is very much an Australian creation, which can be traced back to Sans Souci NSW builder, Terry Quantrill. He pioneered their construction in aluminum, overcoming some of the early technical problems associated with the material and it’s welding, and then developed the market, which eventually saw competitors join and flourish. From the mid-1950s the tinnie became an immensely popular craft throughout Australia, elevating itself into a versatile range of boating applications, and ranging in fitout from the basic to the highly specialized and purpose built model.

In 1945 Quantrill began his career in the boating market by building small thin gauge steel plate motor launches. He promoted them with advertisements recognising the need for a marketing approach to business. The 1946 Seacraft December issue has an advertisement for one model- a 6.3m (21 foot) long raised deck launch, citing the advantages and showing a handsome vessel under the trade name Quintrex, however the company was Quantrill and Arnold, based from his home address The Promenade, Sans Souci on the shores of Kogarah Bay in NSW

The background to the design for this craft is unknown, but another design built by Quantrill came from naval architect Alan Payne, project No 15 dated May 1947 , and very early in his career. It was a 3.365m ( 12 foot) long, single chine, shallow ‘vee’ bottomed ‘putt putt’ that used a 3 hp Simplex engine.

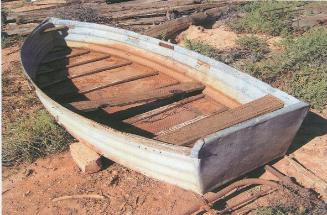

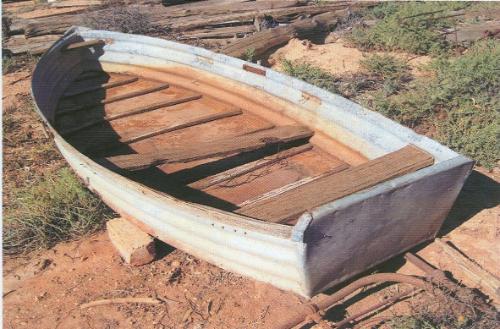

Small metal craft were not unique at this time. Outback Australian’s had created a number of quite individual small metal craft from easily sourced materials such as corrugated iron or steel, and even modified 44 gallon drums. Some of these were quite makeshift and represent the ingenuity of the builder to fabricate something that was quite possibly built as a quick response to a flood situation. Isolated from the mainstream the craft often displayed a curious mixture of boat and farm yard features. In Quantrill’s case he was working in an urban area and had plenty of other craft as a reference point as he pursued his design development of what was to become a single-chine vee-section hull.

The small steel boats Quantrill was building were still relatively heavy, so he decided to work with welded aluminum construction, but needed to overcome difficulties with the fabrication and acceptance of the material. In the late 1940s there had been a short history of people adapting the aluminum drop tanks used on World War II military aircraft as boats, by simply cutting the streamlined tanks in half. However the aircraft grade aluminum quickly corroded in sea water, so there was natural distrust of the material for boats. Whilst one of Quantrill’s first hurdles was proving that better, marine grade aluminum was suitable for a long lasting craft, the other was working out how best to weld the material, a logical method of construction but not then suited to a tradesman’s regular application.

His first method used oxy acetylene which was slow, very tricky and needed significant skill. He then experimented with argon arc welding using high frequency welding machines and T.I.G. welding torches, eventually perfecting the approach that is now comon in the trade, and creating a viable production process.

There are other examples of small aluminum boats elsewhere around the world; one is the punt shaped John Boat from the USA, a derivative of their wooden duck punts and sneak boxes. It is also possible that other enterprising individuals built their own craft, perhaps similar to Quantrill’s concept. However, as a recognized type built in large numbers, the vee-bottom planing tinnie is clearly a craft that was developed in Australia beginning with Quantrill’s work.

In 1951 a big step forward occurred when Quantrill’s friend, boat retailer Ted Hunt, offered the boats for sale through Hunt’s Marine in the south of Sydney. They were 10, 12 and 14 foot long hulls, made from the saltwater-resistant aluminum alloy L-33 supplied by Comalco. From the beginning the lightweight, car-toppable and low maintenance aspects were promoted, and to offset the mistaken belief that a metal hull could not float, Quantrill pioneered the use of foam blocks under the thwarts as buoyant material, so that even if a craft was swamped, it would not sink.

Demand steadily increased and by the early 1950s Quantrill’s backyard operation had moved to factory production in Presidents Avenue in Kogarah, then over to Taren Point. The massive floods in northern NSW during 1954 had created a shortage in the supply of small boats. Graziers had bought almost every available boat to use on their flooded stations to feed stock stranded on higher ground, and the tinnie was the ideal craft. It was robust, could be knocked about without compromising its operation, required little maintenance and was easy to transport, almost tailor made for a non-boating user to adapt to quickly. It was also possible to transport in bulk easily, stacked together on trains or trucks for shipping in larger numbers to regional areas and interstate.

A 1955 Seacraft advertisement by Quantrill and Arnold shows off the advantages of light weight, buoyancy and durability, but quite revealing are some of the dealers mentioned. Along with Sydney’s Hunts Marine are Queensland Pastoral Supplies and Inghams’ Frank Frazers, showing the wide ranging market the type was now exploiting. Boating was no longer a coastal market; the inland waterways were part of the scene as well.

The next big boost came as the market expanded dramatically when large, factory mass production became viable. Early in the 1960s outboard motors became much more readily available when the import restrictions were removed, allowing the popular outboards from the Johnson, Evinrude and Mercury factories in the USA into the Australian market. At the same time the aircraft manufacturers De Havilland were encouraged to enter the market as boat builders. They were well set up to take on the task as they had tradesman familiar with aluminum construction. De Havilland boats, built in the industrial area of Bankstown NSW and promoted as Topper Aluminum Boats were initially built with riveted construction, a reflection of the company’s aircraft background, and over the decade they built craft by the thousands.

Other manufacturers joined the market as it continued to expand and confirm itself as a significant industry which remains strong in 2014. Quantrill’s original backyard business became well established as Quintrex, and it currently makes around 15,000 boats per year, with about 1500 of them for export.

Despite its many attributes, the tinnies’ major success as a mass-produced vessel has been confined to Australia, New Zealand and nearby Pacific and South East Asian markets. Nether the US or European countries have embraced the concept beyond pockets of interest such as southern USA waterways. The main reason is intriguing, an alloy boat is a cold boat to sit on, and this does not suit those northern climates with consistently low water temperatures. There the inflatable and fibreglass boats have remained dominant.

Tinnies are ideal commuter and utility boats and are found in these roles along all Australian waterways, with private, commercial and government body owners. They are low cost to purchase and operate, low on maintenance, robust and easy to handle. These same qualities have helped the tinnie to perhaps its greatest contribution, the access to recreational boating for thousands of individuals and families with little or no boating experience, who just want to go fishing or mucking about on their local waterway or at their favorite camping spot.