The Tasmanian Trading Ketch

Hopefully this introduction paints a picture of the Trading Ketches of Tasmania from a design perspective but another factor also contributed highly to the structure of the ketch. It had to be built strong to withstand the forces of nature an island state would throw at her.

BACKGROUND INFORMATION

In Bass Strait Ketches Harold Salter wrote, “In the main the vessels were stout and locally built, the timbers being cut from the surrounding bush…But without exception they were hard working, economical and superbly handled little craft, which constantly plied some of the cruellest seaways to be found anywhere in the world.

At the time I knew the fleet, the majority were well into middle age, so one cannot help but marvel at the expertise of their masters, crews and shipwrights. They served some of the more remote seaports of Tasmania, Victoria and South Australia, and were the main lifeline for many of the remote coastal towns, settlements and farms until land became sufficiently developed to replace them, where once the wharves were crammed deep with these vessels, the period I write of was the beginning of their demise. Then came WW2 and many changes took place in the fleet. Quite a few were commandeered by the services, in which capacity they more than added to their past glory”.

In “Pioneer Shipping “, L Norman wrote, “No type of craft has been so numerously represented on the Derwent as the ketch…No matter how small or humble some of them may have been, each has been dear to the heart of some one. A little ketch, almost unnoticed on the Hobart wharves, becomes a thing of great importance as it reaches its down-river port, brightening the lives of the small community [it serves so well], gladdening the eyes of those in lonely parts as it sails by.

The ketches have often been alluded to as the “Derwent Fleet”. There have been enough of them to earn that title and many of them have been and are as beautiful as a yacht. Take for instance the following great grandmothers of the fleet – not to mention “Royal William” and “Thames” among the cutters…”

To enlighten us in more recent years Garry Kerr in “The Tasmanian Trading Ketch” wrote, “Every seafaring country has developed distinctive types of craft to suit its particular needs, which were governed by the nature of the waters in which the vessels were to be used, and by the use to which they were to be put. Thus a very different form of hull and rig was evolved on a rocky exposed coast with deep harbours, than in an area where the waters were relatively sheltered and shallow.

In the development of type and rig, tradition has played an important role. The seaman by nature is conservative. What his forefathers had tried and found good, he was slow to abandon. This is not surprising for, after all, one who follows the sea trusts his life to his ship and her gear, and prefers the known and tried to the new and untried. Slow in development there is, of course, but in that development the effect of one’s heritage and tradition is always a dominant factor.

When Australia was first settled by Europeans, the early shipwrights built vessels of a design with which they had been familiar in their home countries or districts, and in the main, most were tolerably well suited to Australian conditions. Over a period of time however, adjustments and changes were made to hull form and rig to suit local conditions, and to keep pace with the general progress in marine engineering.

Much of Australia’s early produce was carried from place to place, and along many miles of open coastline in vessels which seem incredibly small and primitive to today’s standards. Many were lost, but many more continued to trade without serious mishap for quite long periods. The smallest of these traders, the little cutters and ketches of 20 – 40 tons, which traded along the open coastline and supplied the coastal and river communities with the basic requirements of life, and in return freighted the result of the farmers’ and timber cutters’ toil to the larger settlements, were the first to suffer from the competition of the regular steam packet services, which gradually expanded from the 1870’s and 80’s. However in certain other localized trades they [Trading Ketches] were able to compete for a considerably longer period.” Obviously, this changed yet again, as rail and road transport opened up.

DESIGN FACTORS OF THE TASMANIAN KETCH

The foregoing identifies the Tasmania Trading Ketches being in service to Tasmanian communities from the early 1820’s through to the 1950’s. The above quotes also identify that the Tasmanian Trading Ketch service was warranted and of great commerce and community value to outlying Tasmanian settlements. Quite an incredible period of time of service, during which there was a rolling evolution of the design and build of the Tasmanian Trading Ketch.

During the period of the 1820’s and 1950’s there were too many cutters and ketches built to either list all of them or provide an injustice by not accurately recording them all. However, Harold Salter in Bass Strait Ketches states the following; “The list of Tasmanian boat builders from about 1825 reads so: John Gray, Peter De Graves, Daniel Callaghan, John Watson. The last deserves special mention as he assisted many of his subordinates to become master tradesmen. Other names were John Pechey, Charles Chessil, John Ross, John Lucas, Mackey and Cullen, John McGregor, John Wilson, Daglish and Taylor, Harold McKay, Harry Moore, Purdon and Featherstone, WE Tucker, and of course Ernest and Edward Higgs.” Harold goes on to say “… the figure [of Cutters and Ketches built] stand at, [at] least 600 vessels. Not all were tiddlers; some mighty fine barques [as well] came off local slips: big square rigged ships such as …” and he goes on to name many in excess of 500 vessels.

What is also possible is that Harold’s account is only that of larger boat/ship building yards and it could be suggested that there were many other boat yards and builders who contributed to a larger number of Tasmanian Trading Ketches and Passage boats. Passage boats freighted farm produce from outlying districts of Hobart in particular, they were usually small rarely exceeding 50 feet in length and were double-enders. Most were of steam bent timbers (ribs) and planked as batten seam carvel built craft.

We have spoken and quoted earlier of ketch design types that emerged during this period. However, probably because of homeland knowledge the trading ketch was designed along similar lines to the Thames Barges and became known as the Tasmanian Trading Ketch. The term ‘barge’ stuck with many of the designers and builders. Although the Thames Barge carried lee boards the Tasmanian ketches used generally a centre or dagger board. There is also mention in Garry Kerr’s book Trading Ketches of Tasmania that Tasmanian Ketches were modelled on the New Zealand Scow, again another country of English heritage and populated by English descendants originally, perhaps indicating the NZ Scow being of English maritime heritage and design also.

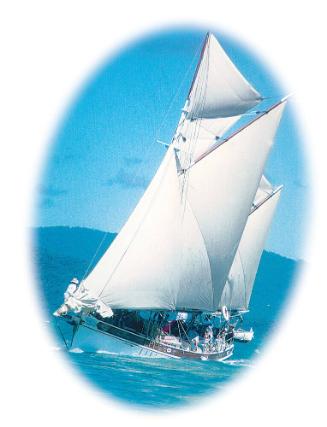

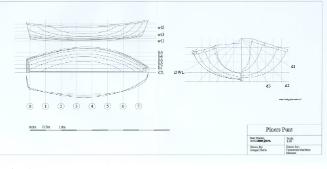

The lines of LUNAWANNA are depicted in Garry Kerr’s book The Tasmanian Trading Ketch. A hallmark of the Tasmanian Trading Ketch generally was that it had a clipper bow and counter stern. The lines are quite similar to those of a Thames Barge apart from the Thames Barge’s spoon bow and no counter stern. As well, the Thames Barge was generally Sprit rigged. The photos of the Tasmanian Trading Ketch LUNAWANNA and the Thames Barge ARDWINA show the similarities well.

The relatively flat bottom and vertical topsides were also a classic and typical feature for decades, and this could be attributed to the design of similar craft in other parts of the world. However it can be said the need to operate in shallow waters, to be able to stand upright on tidal flats and carry a reasonable load to make the operation viable will always generate a roughly box section shape for the vessel being considered, and low freeboard seems to always come into the picture too. It works well for the operational aspects of loading and access to the cargo, but the box section shape always carries a warning for stability. As a shape it does not produce good additional form stability when the hull heels, the margin is not high and the capsizing point of no return can be reached early, a factor made worse by the usually higher centre of gravity developed from the load of the cargo. A slight shift in the cargo at sea or lack of attention to sail in squalls can bring the craft to a point of danger quickly. This text book observation though was countered by the seaman’s understanding and feel for their craft and the sea, generated from their own experience that was first passed to them by their forebears. It was this knowledge held by skipper and crew that allowed them to operate safely and although capsizes happened, the vast majority of voyages were undertaken safely.

In the trading ketch the box section was enhanced with a very shallow dead rise and rounded bilge, while the profile had an elegant clipper bow and overhanging counter. The round bilge shape although wide was elegant with a nice run to waterlines and buttocks. In comparison the scow shape with its hard chine and veed bow (as used in NZ) was more functional but less pretty to the eye and to the feel of a hand run over a ½ model. Less than a handful of scow versions of the trading ketch were built, it seems the builders remained true to their smoother rounded shape, a worthy hull form for the Tasmanian timber used to build them.

A final note on the box section and its limitations came in the evolution of the craft as influenced by the annual trading ketch race at the Hobart regatta. To be cock of the fleet was a prize worth striving for by whatever means, and most craft had their once-a -year suit of racing sails to help them in the endeavour. However, in the latter period of the ketch one of the last ones built, TERRALINNA, had a narrower, more veed hull section- a shape that helps with sailing to windward and stiffens up as it heels- two race winning attributes hard to live without once tasted.

In Rick Bullers’ thesis on “The quality of construction of Australian built colonial period wooden sailing vessels lost in South Australia and Tasmania”, Rick summarises his hypothesis making the following statement;

“Although research into shipbuilding during the Australian colonial period has been underway for more than 20 years, the industry is still little understood.

The majority of Australian-built vessels were small coastal traders and there is a paucity of available information in the historical record. To paraphrase others, the vessels that plied the Australian coastline may be termed ‘ships without voice.’ Yet these vessels were vital for the expansion of settlement throughout the colonies.

A high attrition rate and low vessel working life prompted historians to claim that early Australian-built vessels were of poor quality when compared to foreign-built vessels. A more recent statistical analysis has shown that early Australian-built vessels did not have a markedly different attrition rate to foreign built vessels operating on the Australian coast. It has been stated that Australian-built vessels, rather than being poorly-built, were cheaply built, and that these vessels were built relatively lightly.

This thesis aims to use the material record to lend validity to the quality of Australian-built vessels, targeting one particular aspect of construction – scantling dimensions – to test the hypothesis that Australian-built vessels were constructed to a similar standard as those built offshore. The study has shown that scantlings on Australian-built vessels were at least as good as, and often exceeded, contemporary standards.

THE STRUCTURE AND BUILD OF A TYPICAL TASMANIAN KETCH

The building of ketches in the early days was hard work for man or beast, generally horse or bullock. There were no power tools simply shaping, rebating and scarfing by axe, broad axe and adze after the logs and scantlings had been fallen and then roughly cut in a saw pit. Before cutting could commence a pit had to be dug and the keel log set up on blocks so it could be moved over the pit for full length cutting. As by way of “necessity being the mother of invention” there are records of some long keel logs being drill centrally at equal distances and then loaded with gelignite and roughly split with gelignite before pit sawing.

The Tasmanian method of ketch construction was known as “frame built”, that is solid frames although some were laminated at the turn of the bilge only if suitable grown frames, known also as “crooks” could not be found in the bush. Generally the shape of frame at each station would have been taken off a ½ model of the ketch enabling the finding of and then shaping of the solid frame to occur in the bush and then transported back to the yard. Once stood up and fastened to the keel floors were installed to support the frame. Sometimes double frames were used for additional strength. At this stage some internal longitudinal stringers and shelving were fitted, thus strengthening and bracing the frame of the vessel for both the build and once at sea.

As time moved on it became common for frames to be sawn to shape at the boat yard. Once the frames were in place planking could commence and often was done by fixing one plank, then missing a plank and fixing the next. This was known in Tasmania as “bird caging”. It had the distinct advantage of allowing the first set of planks to dry and harden before the intermediate planks were then fitted tightly and caulked. In early days “trunnels” or treenails were used to fix planks. Trunnels were basically a wooden dowel from 1” to 1.5 “made in a variety of ways. The plank and frames were drilled accordingly and the trunnel driven in hard. Once in the water the trunnel would swell and basically become part of the wood in the frame and the plank proving one of the strongest fixtures. However, by the 1940’s all fixings had changed to iron, steel or other metals.

Once planked the deck would be laid followed by deck structures such as cabins, forecastle companion ways, hatches and coaming, plus the deck hardware of Samson Posts and bollards. Then the masts were stepped using blocks, tackle and shear leg with a horse or bullock doing the pulling to step the mast. Following this, the rigging was seized to the blacksmiths hardware that had been appropriately fixed to the ketch.

As confirmed in Rick Bullers thesis, the Tasmanian Trading Ketches as “Australian-built vessels did not have a markedly different attrition rate to foreign built vessels operating on the Australian coast. It has been stated that Australian-built vessels, rather than being poorly-built, were cheaply built, and that these vessels were built relatively lightly.”

The following is an account of the construction of a Tasmanian Ketch built in Port Albert, Victoria. The ketch was the Annie Taylor built in 1920 by father and son shipwrights, Edward and Ernest Higgs, both ex Tasmanian shipwrights, and owned by the Taylor Brothers which served Tasmania well up until 1924 when she was wrecked at Rheban Beach due to having to leave the wharf in high winds laden with timber, after which she foundered and was lost on Rheban beach.

She was a wooden (the last known trunnel built ship in Australia) ketch with the following details; O.N. 132,437, wooden 2 masted ketch, round stern, clipper bow, 103.25/95.75 gt, net 88.0X22.5X8.0ft. She frequented Melbourne, Sydney, Wollongong, Adelaide and many Tasmanian ports trading timber and general cargo.

“The memories now of a small boy then at Fathers Port Albert boat building yard.

Firstly, the rough log about 90’ [long] was hauled to the yard by bullock wagon with a tough whip swinging, “multilingual bullocky” depositing some tons of the log into the desired position to be squared and shaped 12” X 12” its full length before being rolled over, raised and aligned on the building stocks. The 2” thick (off the saw) planking arrived next, this almost flawless beautiful timber quarter cut with one sawn straight edge, the other side had the bark left on, this allowed the plank to naturally pull edge-wise into a slight curve as the timber dried out, a great help to those who planned the vessel. As these planks were unloaded they were laid with a gap between on battens on the flat ground and turned over each day. The other framing timber arrived within a few days, these pieces (scantlings) were for stem and stern, framing, gunwales, stringers, shelves, deck beams, bulwark-stanchions, rail capping, sampson posts, cavils etc. The main frames solid and some laminated, especially at the bends at the turn of the bilge were cut in the bush from natural ‘knees” and to the shape of the templates taken from the model [half] then full sized by Grandfather. These knees and curved pieces were brought back to the yard by dray or sledge.

Framing construction was done on a rough planked platform square across the keel now in position on stocks, each frame 2 layers laminated to full size (mould) template was fastened through with 1’ diameter trunnels (tree nails) and after the stem and stern framing was shaped and fixed in position the solid frames were hauled up vertically, one after the other working from forward to stern, and hauled by the willing “Bonnie” through blocks, tackle, shear leg and all correctly positioned, this almost human white draught horse understood exactly what was required, start and stop, and carefully avoided as much as possible stepping on timber. Decking timber was imported [from Tasmania] a quarter cut 2” thick Celery Top pine had come through Melbourne via the coastal steamer Moonah and unloaded at a wharf not half a mile away. Just a few miles away at Alberton a farmer known to Dad had each side of his entrance to the farm house an avenue of fine pine trees , not the usual pine these were Douglass Fir or similar, straight and small limbs and sound quality however, Dad and Grandfather visited this farmer often and finally persuaded him that a couple of the trees on the south side were sticking out of line and the Avenue could be vastly improved, so they were sold a couple, that’s where the main and Missen Masts came from and apart from a few cracks on drying out they were sound “sticks”. The top masts and booms and yards were from timber yard Oregon. Bow Sprit, cross trees also Oregon. Cat’s heads and hounds were from strong hard wood as were the Samson post, fwd and Bollards aft and at breast hooks grown knees.

As time progressed and various parts and pieces were shaped to bevel and with adze, axe or broad-axe, cross curt saws- the yard became covered with wood chips, these were not gathered up in the winter as they kept away the wet mud underfoot.

A rough vertical boarded shed to the north housed the tools, trunnel making machine (hand operated), Oakum Stockholm tar etc. Trunnels’ were made on wet days and too talkative visitors to the yard when hanging around would be asked to turn the handle at a large wood “flywheel” with a rope belt connected to the iron hollow-head, it was fitted with two hand plane blades which on rotation would shave the square stock timber to round trunnels.

The square wood was held in a two handle stock and inserted in the rotating iron head, pushed in about 18” and pulled out a clean full 1” dowel like “tree nail”. The square wood was very special good stock and straight grained. These, when being used, were dipped in Stockholm tar. Planking was carried out after being set out stem and stern and amidships by what was then called the “bird cage” method, Sheer strake (wide) fitted and fixed full length [at the top of the frames]. Garboard strake next [adjoining the keel] then every second one through-out the hull, full length fore and aft. This enabled all planks to dry out and season with enough moisture content for bending purposes and 2nd or intermittent planks were fitted as late as possible and driven home tight and fixed prior to caulking, hull planed off by hand before the hardwood became too hard to plane. The laying of the celery top deck came soon after spiked down with galv. “E.W. Bank” spikes, caulked and oiled.

Deck houses next, Main then the aft main cabin and fo’castle companion way with sliding curved top and slide down wash rails, Hatch Coamings around the main cargo hatch and strong-back fore and aft then hatch covers fitted within and provision on the outside for canvas cover battens and iron lugs for wedges. The masts were stepped using a shear leg guyed in position and “Bonnie” doing the hauling through blocks, iron work made by the blacksmith in Alberton or Yarram fitted before stepping and all tarred or painted black.

As a boy I remember roaming the decks while Captain Taylor and 2 hands, one I think his son, carried out the standing and running rigging prior to launching. Lots of other gear was fitted such as the rudder and steering gear to wheel aft (cross at that time). Bow-sprit rigging, bob-stay, port and starboard stays, bands and lugs, huge deck bilge pump lever operated and emptied over the deck to scuppers. The cargo hold was completely lined over the frames and floored each side of the keelsons and forward bulkhead abaft focastle back to Captain’s cabin aft. The distance between these bulkheads determined cubic carrying capacity of the Ketch, and this determined crew numbers who should be manning the vessel.

However, Mother broke the bottle of champers over the bow after several bounces and with a lot of tapping of wedges and grinding noises she slid down the ways and came to rest by the old jetty. A crowd turned up to the launching, a man on the gate collected a few pounds for the local Hospital.

I was in one of four fishing boats, 2 each side and towed the Annie Taylor down the harbor and across the bar from which she (no engine) sailed away to Tasmania.

E.W. Higgs” (sourced from Higgs Family records)

The above is a rough account of the Tasmanian Trading Ketch build process. Other research books and documents on Tasmanian Trading Ketches stated, “That mainly the process of building a ketch was knowledge only to those who built them, and that those people had passed on before it was rightfully documented”. The above account is that of the son and grandson of the Annie Taylor shipwrights.

Text by Peter Higgs, Research Assistant ARHV

Person & vessel typeVessel type