Clump Point Indigenous Sewn Bark Canoe

Vessel numberHV000588

Vessel type

Indigenous Watercraft of Australia

Date1905

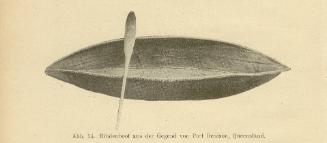

DimensionsVessel Dimensions: 2.4 m x 0.61 m (7.87 ft x 2 ft)

Vessel Highlights

The canoe is the same type as HV000585 ( AM number E010084) and from the same region. It features a supporting structure made of additional sheets of bark, frames, gunwale branches and cross ties This structure contrasts with similar canoes on the western or gulf side of Cape York such as the skinbark canoe HV000444 from Mapoon which features a cross bracing system instead of frames.

Roth was appointed as Queensland's first Northern Protector of Aborigines in 1898 and was based in Cooktown, Queensland. From 1904 to 1906 he was Chief Protector and recorded aspects of Aboriginal cultures in the region. Roth’s Bulletins (AMTR 1996: 99) have early descriptions of the construction of these canoes. Construction began by stripping the bark of a eucalyptus tree at the end of the wet season, a time when the rising sap made the process of removing the bark from the sapwood much easier. The bark sheet was then inverted so that the inner layer of strong and resin rich fibres became the outside surface of the finished canoe. Both ends of the canoe were then heated over a fire to make them pliable. As soon as an end became pliable it was clamped in a vice. The vice was made of two branches set into the ground and tied together at the base forming a fork. The end of the bark was folded as it was pushed into this fork and then pulled together by tying the fork at the top end. A short piece of branch kept the sides of the bark spread apart.

A sharp-edged shell was used as a cutting tool to shape the bow profile with a little amount of rake. The bow was then sewn together with a split strip of lawyer cane passed through drilled holes and overcast around the exposed ends of the canoe’s bark sheet. The sewing process was started at the centre working first downward and finished with the upper section being sewed. Then the opposite end was heated, folded and sewn in the same manner.

With the ends secure and the spreader branches in their place, two strong flexible branches were attached to the inner side of the top edges on both sides, acting as gunwales; these were overcast with strips of lawyer cane and sewn to the bark edge. Then additional layers of bark were laid crosswise inside the canoe to strengthen the bottom. These pieces of bark were then held in position with the frames or ribs made of split lawyer cane which was pushed into place with their ends secured between the gunwale branches and the bark. The spreader branches were then removed, and a single tie was sewn across the top at about the centre of the vessel to prevent the two sides from springing apart. Lastly a heavy stone was tied to a rope to make the anchor which was fixed through a hole made at the top of the canoe.

This description is appropriate to this canoe except for the following observations: it appears not to have had the bark inverted; there is an additional bark sheet sitting in the base lengthwise that may be a floor sheet to sit on over the frames; it has gunwales made of three branches; and two cross ties along the hull.

The canoe was usually paddled by a small oval-shaped piece of bark, or a large pearl shell in each hand and a shell bailer was usually on board. As well, there is usually material to start and keep a fire built over a clay or possibly stone hearth. These items are not with this craft.

The canoe is currently stored at the Australian Museum as part of their extensive collection of Indigenous watercraft.

SignificanceThe Indigenous sewn bark canoe E013452 from the Australian Museum collection (E013452) was made near Clump Point, Cardwell in NE Queensland on the eastern side of Cape York Peninsula. It represents the design and construction of this region's bark canoe which was primarily used on the local rivers, but is also a type recorded operating on the coastline on short passages to offshore islands within the Great Barrier Reef. The canoe was acquired by Queensland Northern Protector of Aborigines and anthropologist Walter Edmund Roth while on an expedition in the area in the early 1900s.